ABS/PS chassis broken cleaning production line

Name: ABS/PS chassis broken cleaning production line

Model: ABS/PS appliance waste line

Raw material:

Usage:

Main machine:

ABS HIPS TV shell, ABS washing machine shell, refrigerator shel,l air conditioning shell PS car, electric car battery shell

◆ The grinding system adopts wear-resistant design to ensure the continuous and stable operation of the system for a long time

High speed centrifugal cleaning system with the most suitable rotation speed to different materials to apply the corresponding blade hitting force, cleaning effect is good

◆ Dry electrostatic separator mainly uses the principle of high voltage electric field separation, the same unit voltage electric field in different materials with different charge series of the principle of different materials for the separation of materials, no waste gas waste water solid waste generation, no pollution, no environmental pressure.

◆ Specially designed air flow and air separation system can effectively separate the light materials such as sponge and dust in the separation of home appliances to improve the purity and recovery efficiency of all kinds of materials

◆ High efficiency magnetic drum magnetic separation system separation materials in the steel and control the purity of steel materials, because of its special working mode, in the separation of steel is not easy to absorb impurities

The whole line automation control, the system between the unit operation, high degree of automation

Adopt circulating water to ensure the cleaning effect and reduce the water consumption

◆ After theoretical calculation and many times of actual measurement, the mechanical operation details of crushing, cleaning and drying are adjusted to avoid material loss caused by excessive treatment

◆ The production line can be equipped with sewage and wastewater treatment system, which can precipitate, filter and recycle the sewage to meet the standards of environmental protection, and solve your worries at home

In the refrigerator, air conditioning, television sets, washing machines and other electrical appliances, the material such as PP, PS, ABS, PVC plastic occupies small proportion, and the value of these plastic compared to other material of plastic is relatively high, therefore, how to fast and convenient to plastic separation and recycling of household appliances and other industries urgent concern.

Resource is not only home appliance of recycled plastic, therefore, after crushing processing of waste household appliances for first to all kinds of metal resources sorting out, and then to separation of broken plastic, the other for sorting of waste plastics are also should be broken state, if not, we also have plastic granulator of plastic products, convenient for sorting. Therefore, the separation of waste plastic, can also be said to be the removal of impurities in the plastic crushing material.

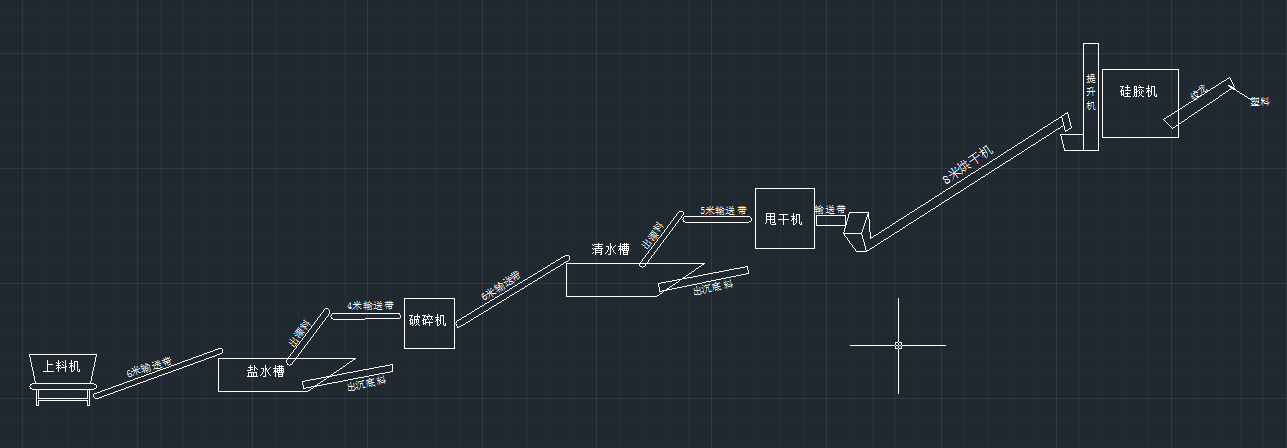

Reference of sorting line: Plastic mixed crushing material → feeding machine (uniform conveying material) → salt water drift tank (remove heavy objects such as stones, metal, leaving all kinds of plastic and other light floating objects lighter than salt water) → plastic crusher (to break mixed plastic,) → clear water drift tank (cleaning plastic, The plastic according to the material material simple distinction) → dryer (to water) → dryer (drying) → silica gel machine (remove rubber, silica gel and other impurities, get relatively clean plastic, according to the different materials, purity in 99%+).

At this point, the relatively clean plastic can be sold, its value compared to the original mixture improved a lot, so there are a lot of people will buy the material sold after sorting, earn price difference), and, of course, if necessary, we can also to the next step of purification of plastic, we will continue to increase its value.

After sorting out the relatively clean plastic, we can also separate the plastic of different materials through the electrostatic sorting machine. After that, we can also use the color sorting machine to separate the plastic of the same color.

Electrostatic sorting machine, using 1+2 type sorting. The principle takes advantage of the different electrical properties of plastics of different materials to separate plastics according to their materials. Color sorting machine, divided into waterfall and caterpillar type.

Main equipment:

|

|

Mobile site

Official WeChat